The published circuit board assembly, or PCBA, is the basic element of virtual devices. Today, you can use a smartphone, a computer, and a TV. All of these gadgets require an inner circuit board to function. But what does a PCBA suggest, and why is it so vital? In this text, we can explain the PCBA in simple phrases and show how it enables bringing digital devices to life.

What is PCBA?

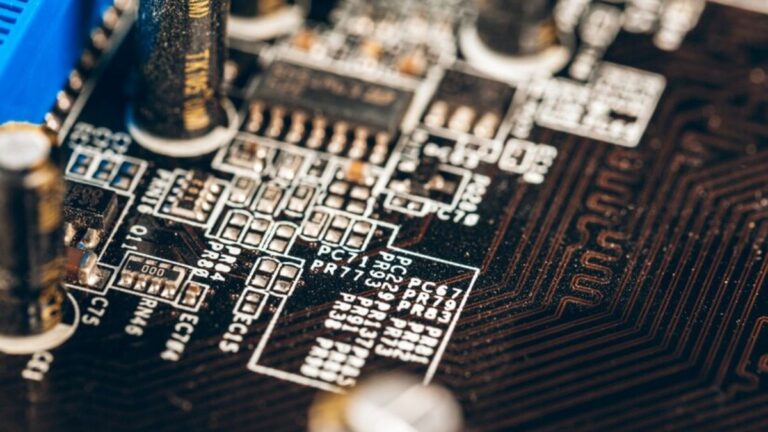

PCBA stands for Printed Circuit Board Assembly. It is the system of putting digital additives on a broadcast circuit board (PCB). A PCB is a flat board, ordinarily green, with copper wires, which facilitates behavior strength. These copper wires act like conduits that convey electric indicators to distinctive elements of the panel.

Without the PCBA, the PCB is just a blank board. The PCBA system makes the board work by way of adding electronic additives, together with resistors and capacitors. This is an important step due to the fact it’s far the handiest circuit board capable of powering an digital device.

PCBA Meaning in Simple Words

The PCBA meaning good judgment is easy: it assembles a circuit board using digital additives. These elements help the device perform unique responsibilities. For instance, on your cellphone, the circuit board connects all of the different components (which include display, buttons, and digicam) so that you can work collectively.

What Parts are on a PCB?

There are many small components that might be needed to make a PCB painting. Here are a few common parts determined on a PCB.

Resistors: These manage the float of strength.

Capacitors: These save and release electricity.

Diodes: This behavior strength in only one route.

Transistors: These are like strength-off switches.

Integrated circuits (ICs): These are small chips that carry out vital duties consisting of statistics processing.

Connectors: These connect the PCB to different elements of the machine.

All these elements are linked to the panel through copper cables, which provide electricity and energy to the system.

How Does PCBA Work?

The PCBA layout requires several steps to ensure proper operation of the circuit board. Let’s go through these steps in simple terms:

- To practice solder paste

The first step is to use solder paste to the PCB. Solder paste is a viscous mixture of small metallic balls and flux.

- Installation of electronic additives

Then, the machines (or, from time to time, humans) place the small digital components on the PCB. The machines are very accurate and might set up the parts quickly. For the board to be painted appropriately, every element should be in its proper area.

- Soldering of components

Once the parts are placed on the board, the PCB is heated in a unique furnace. This method is called reflow soldering. The warmness softens the solder paste and creates a strong bond between the components and the board.

- Management of the Board

After the soldering is finished, the board is inspected for faults. Analysis can be executed by machines or human beings. This step is necessary to ensure that every component is in the correct area and nicely connected.

- Review of the board

The ultimate step is to test the PCB meeting. The board is examined for predicted performance. If it passes the check, it could be used in the system. If there are any issues, they are constant earlier than the panels are used.

Types of PCB Assembly

There are essential styles of PCB assemblies: through-hole era (THT) and surface mount era (SMT).

Through-Hole Technology (THT): Parts in have metallic legs that skip through a hollow in the PCB. This leg is soldered to the other aspect of the board. This method is robust and is regularly used on large or heavy items.

Surface Mount Technology (SMT): In SMT, the parts are mounted directly on the PCB surface without holes. This method is much faster and allows smaller particles to be produced. Most present-day digital gadgets use SMT.

Why is PCBA Important?

The PCBA may be crucial as it turns a blank circuit board into a running tool. Without the PCBA, a circuit board would just be a purposeless item. Here are a number of the motives PCBAs are crucial:

Equipment Function: The PCBA connects the digital components to operate the device.

Multi-manufacturing: PCBAs allow manufacturers to manufacture more than one device simultaneously. Machines can rapidly gather lots of bars, making it more straightforward and inexpensive to make electronics.

Precision: The PCBA machine ensures that every one elements are installed and assembled well. This accuracy is vital because even the slightest mistake can clog the system.

Lower price: Automated PCBA production facilitates reduce production prices by means of reducing exertions and speeding up manufacturing. This makes the production of many digital devices pricey.

Quality manipulation: The inspection and trying out section guarantees that the handiest, highest, and most friendly panels are used within the machinery. This facilitates save you mistakes and ensures that the device will work as predicted.

Where is PCBA Used?

PCBAs are used in nearly every electronic tool you may consider, e.g..

Smartphones: Every telephone has integrated additives via a PCB.

Computer: Your computer has a motherboard PCB that passes via the PCBA.

Medical Devices: Many clinical devices, including cardiac monitors and imaging devices, depend upon PCBAs to function well.

Cars: Today, automobiles are packed with electronics, from engines to leisure systems, all linked and controlled using PCBs through PCBAs.

Conclusion

In simple terms, PCBA which means is the system of including digital components to a printed circuit board to make it paintings. PCBA is a critical step in making all of the electronic gadgets we use each day, from phones to automobiles. By information what PCBA is and how it works, we are able to higher recognize the technology behind the gadgets that make our lives easier.