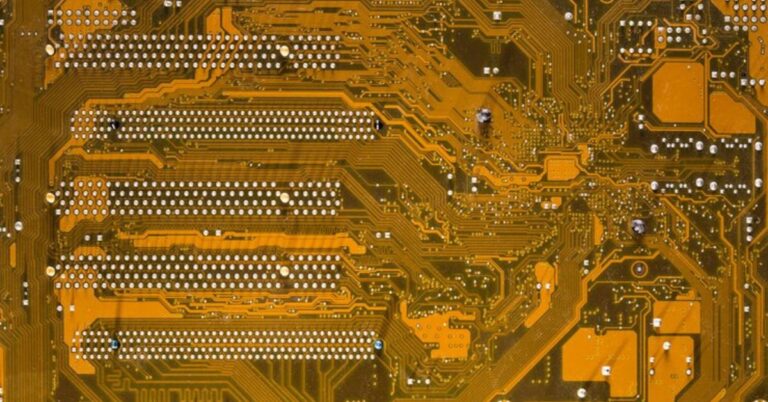

Definition Of SMT: A Modern Approach to Circuit Board Design. In the realm of electronics, innovation drives progress. One such innovation that has significantly transformed circuit board design is Surface-Mount Technology (SMT). This article delves into the intricacies of SMT, exploring its evolution, advantages, components, assembly process, challenges, and future prospects.

TRENDING

QXEFV: Pioneering the Future of Quality and Functional Innovation

Defining of SMT Surface-Mount Technology

Surface-Mount Technology (SMT) represents a contemporary methodology for constructing printed circuit boards (PCBs). Unlike the conventional Through-Hole Technology (THT), where components are mounted by inserting leads through holes, SMT involves directly soldering components onto the surface of the board.

Evolution from Through-Hole Technology (THT)

Historically, circuit board assembly predominantly relied on Through-Hole Technology. However, as the demand for smaller, lighter, and more efficient electronic devices surged, SMT emerged as a superior alternative. Its compatibility with automated assembly processes and capacity for miniaturization propelled its widespread adoption.

Advantages of SMT

Miniaturization and Space Efficiency

SMT facilitates the use of smaller components and enables higher circuit density. This compactness not only conserves space on PCBs but also contributes to the overall reduction in the size of electronic devices.

Enhanced Electrical Performance

The shorter interconnection lengths in SMT result in lower parasitic capacitance and inductance, thereby enhancing the electrical performance of circuits. This translates to improved signal integrity and reduced electromagnetic interference (EMI).

Improved Thermal Management

With components mounted directly onto the surface of the board, SMT facilitates more efficient heat dissipation. This is particularly advantageous in high-power applications where effective thermal management is crucial for device reliability and longevity.

Components in SMT

Basic Components

- Resistors and Capacitors: These fundamental passive components are essential in controlling the flow of electrical current and storing electrical energy.

- Diodes and Transistors: Active components like diodes and transistors play pivotal roles in signal amplification, switching, and rectification within electronic circuits.

Advanced Components

- Ball Grid Arrays (BGAs): BGAs are advanced packaging technologies characterized by an array of solder balls arranged beneath the component. They offer high pin counts and superior electrical performance.

- Quad Flat Packages (QFPs): QFPs are surface-mount integrated circuit packages featuring a flat body with leads extending from all four sides. They are commonly used in applications requiring moderate pin counts and ease of assembly.

SMT Assembly Process

Preparation Phase

- Designing the PCB Layout: The PCB layout is meticulously designed using specialized software, considering factors such as component placement, signal integrity, and thermal management.

- Component Selection and Procurement: Careful selection of components is crucial to ensure compatibility with the intended application and adherence to design specifications.

Soldering Techniques

- Reflow Soldering: In reflow soldering, solder paste is applied to the surface of the PCB, and components are placed on top. The assembly is then heated in a controlled environment, causing the solder to melt and form reliable electrical connections.

- Wave Soldering: Wave soldering is primarily used for through-hole components. The PCB is passed over a wave of molten solder, which selectively solders the component leads to the board.

Inspection and Testing

- Automated Optical Inspection (AOI): AOI systems utilize cameras and image processing algorithms to inspect the solder joints and component placement for defects such as misalignment, solder bridging, or insufficient soldering.

- In-Circuit Testing (ICT): ICT involves testing the functionality of electronic circuits by applying predetermined electrical signals and analyzing the responses. It helps identify defects in individual components or circuit connections.

Challenges in SMT Design

Despite its numerous advantages, SMT design presents unique challenges that must be addressed:

- Component Placement Accuracy: Achieving precise component placement is critical to ensure proper electrical connectivity and avoid signal integrity issues.

- Thermal Management Concerns: The compact nature of SMT assemblies can lead to localized heating and thermal stress, necessitating efficient thermal management strategies.

- Compatibility with Lead-Free Soldering: The transition to lead-free soldering materials poses challenges related to solder joint reliability, wetting characteristics, and process compatibility.

Future Trends in SMT

As technology continues to evolve, several trends are expected to shape the future of SMT:

- Integration with IoT and Wearable Technology: SMT will play a pivotal role in the development of IoT devices and wearable electronics, where small form factors and energy efficiency are paramount.

- Advancements in Automated Assembly Techniques: Continued advancements in robotic automation and machine learning algorithms will further enhance the efficiency and reliability of SMT assembly processes.

Conclusion

Surface-Mount Technology (SMT) has revolutionized the field of circuit board design, offering unparalleled advantages in terms of miniaturization, electrical performance, and thermal management. Despite its inherent challenges, SMT remains at the forefront of electronic manufacturing, driving innovation and enabling the development of increasingly sophisticated electronic devices.

ALSO READ: Kingymab

FAQs

- What is Surface-Mount Technology (SMT)?

Surface-Mount Technology (SMT) is a method used to construct electronic circuits in which components are mounted directly onto the surface of printed circuit boards (PCBs). - How does SMT differ from Through-Hole Technology (THT)?

Unlike Through-Hole Technology (THT), which involves inserting component leads through holes in the PCB and soldering them on the opposite side, SMT components are soldered directly onto the surface of the board. - What are some advantages of using SMT?

SMT offers advantages such as smaller component size, increased circuit density, improved electrical performance, and better thermal management compared to traditional THT methods. - What are some challenges associated with SMT design?

Challenges in SMT design include component placement accuracy, thermal management issues, and compatibility with lead-free soldering processes. - What can we expect in the future of SMT technology?

The future of SMT technology is likely to involve further integration with emerging technologies such as Internet of Things (IoT) devices and wearable electronics, as well as advancements in automated assembly techniques.