Understanding Grease Traps

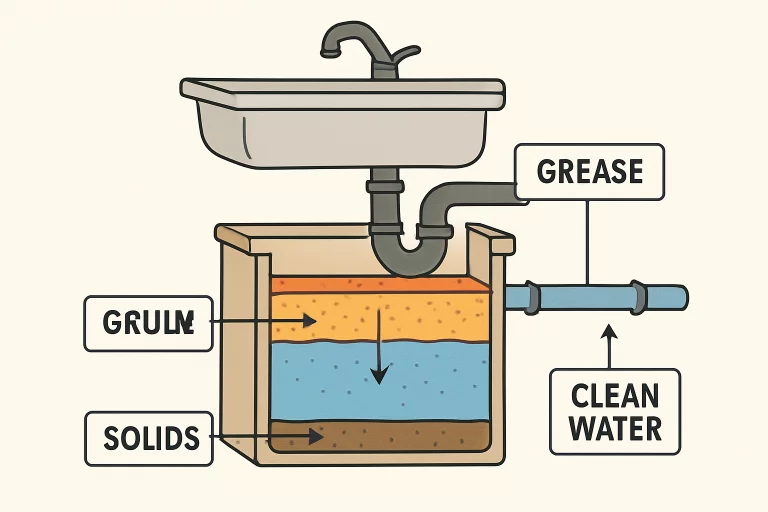

Grease traps, sometimes called grease interceptors, are indispensable plumbing components for any kitchen or business generating FOG-laden wastewater. Their core function is to intercept and collect grease, oils, and solids before these substances can enter the sewer system. Grease traps utilize a separation process, slowing wastewater flow so that heavier solids settle to the bottom, lighter oils and grease float to the surface, and only filtered water moves onward into the plumbing. This simple yet effective mechanism prevents solidified fat from building up within pipes, which could otherwise constrict flow or fully block the drainage. For commercial kitchens, where high-frequency cooking yields significant FOG output, properly functioning grease traps are not just recommended; they are absolutely essential for business continuity and legal compliance.

The importance of grease traps extends to food trucks, bakeries, cafeterias, and even schools or hospitals with food service facilities. Regular grease trap cleaning plays a critical role in maintaining this equipment’s effectiveness, ensuring that accumulated fats and solids don’t overwhelm the system or cause costly backups. Understanding how a grease trap works and why it must be routinely serviced empowers business operators to protect their infrastructure, avoid violations, and support the well-being of the wider community.

Preventing Sewer Blockages

Fats, oils, and grease are notorious for causing severe blockages in both private plumbing and municipal sewer systems. As FOG cools, it solidifies and clings to pipe walls, gradually forming constrictions that restrict water flow. Over time, these buildups combine with other materials such as wipes, food scraps, or debris to form massive, resilient clogs known as “fatbergs.” Such obstructions present significant challenges for public infrastructure, often requiring expensive repairs and posing grave risks of sewer backups and overflows into streets, businesses, and waterways. According to guides like WikiHow’s tips on cleaning drains, routine maintenance and awareness of what enters your drainage system are critical steps in preventing such disasters. The repercussions for businesses can include sanitation crises, negative publicity, and major disruptions to service.

Preventive maintenance minimizes the chances of emergency service calls, property damage, and compliance issues. With consistent care, businesses benefit from unobstructed water flow and stable operations, while also supporting the functionality of local water treatment facilities. This proactive approach not only saves money but also keeps businesses running smoothly, safeguarding against downtime and regulatory penalties.

Avoiding Costly Repairs

Neglecting grease trap maintenance allows FOG and food solids to overflow into the plumbing, leading to internal corrosion, leaks, and severe pipe blockages. Clogs can cause wastewater to back up into kitchens or dining areas, resulting in unsanitary conditions and major operational disruptions. Such damage typically triggers significant expenses linked to pipe repairs, emergency cleaning, water damage restoration, and even the loss of business during shutdowns. Moreover, repeated blockages may shorten the lifespan of plumbing infrastructure, resulting in even higher long-term repair costs.

Routine maintenance is a proven strategy for risk mitigation. By scheduling regular cleaning and inspections, property owners and facility managers can detect and address issues early, dramatically reducing the chances of unexpected failures. Proactive grease trap care can help businesses save thousands of dollars annually by avoiding the high costs associated with plumbing emergencies, environmental remediation, and lost productivity. It’s not merely a matter of compliance—it’s a smart business decision that protects assets, enhances operational reliability, and fosters a safer, more hygienic work environment.

Ensuring Compliance with Regulations

Local and national regulatory bodies recognize the threat posed by FOG to public health and infrastructure, prompting strict ordinances for food service operations. FOG, which stands for fats, oils, and grease, can accumulate in sewer systems and cause serious blockages, overflows, and environmental hazards. According to Water & Wastes Digest, FOG is a major contributor to sewer overflows and infrastructure damage, making proactive management essential for commercial kitchens. In most U.S. states and municipalities, food service establishments are legally required to install, maintain, and periodically inspect grease traps. Failure to adhere to these standards can result in steep fines, costly legal battles, and even forced business closures. Regulatory authorities may also mandate specific record-keeping and documentation to ensure ongoing compliance.

Keeping up with local codes is not just about avoiding penalties—it demonstrates a commitment to responsible waste management and public health. By maintaining up-to-date records of cleaning and inspections, businesses can quickly provide evidence of compliance during health department audits or environmental inspections.

Promoting Environmental Responsibility

Proper grease trap maintenance goes far beyond internal efficiency—it is a vital aspect of environmental stewardship. When FOG escapes into stormwater or wastewater networks, it can travel untreated into rivers, lakes, and oceans, where it degrades water quality, harms aquatic organisms, and contributes to widespread pollution problems. By containing FOG within grease traps and ensuring it’s disposed of through environmentally safe practices, businesses help maintain the health of local ecosystems and reduce their environmental footprint.

Today’s consumers are increasingly attentive to corporate social responsibility, and environmentally mindful businesses enjoy enhanced reputations and stronger community ties. By prioritizing effective grease disposal, companies not only comply with environmental regulations but also position themselves as leaders in sustainability. Partnering with professional cleaning providers ensures that disposed grease is handled according to the latest environmental guidelines.

Best Practices for Grease Trap Maintenance

- Regular Cleaning and Inspection: Schedule professional cleaning every 1–3 months, based on kitchen usage and local regulations. Routine inspections help detect early signs of clogs or wear, preventing breakdowns and maintaining system efficiency.

- Employee Training and Engagement: Train staff to pre-scrape food waste and avoid pouring grease down drains. Use signage and regular reminders to reinforce good habits, improving grease trap performance and extending maintenance intervals.

- Record-Keeping and Documentation: Maintain accurate logs of all cleanings and inspections. These records support regulatory compliance, simplify audits, and help adjust maintenance schedules for greater efficiency.

- Partnering with Professionals: Work with trusted service providers like Affordable Septic Pumping to ensure thorough cleaning and early problem detection. Professionals help maintain legal compliance and protect your plumbing infrastructure.